Numerical Control Spinning Machine

Category:

Spinning machine

Tel:

E-mail:

Product display

Integrated steel ring

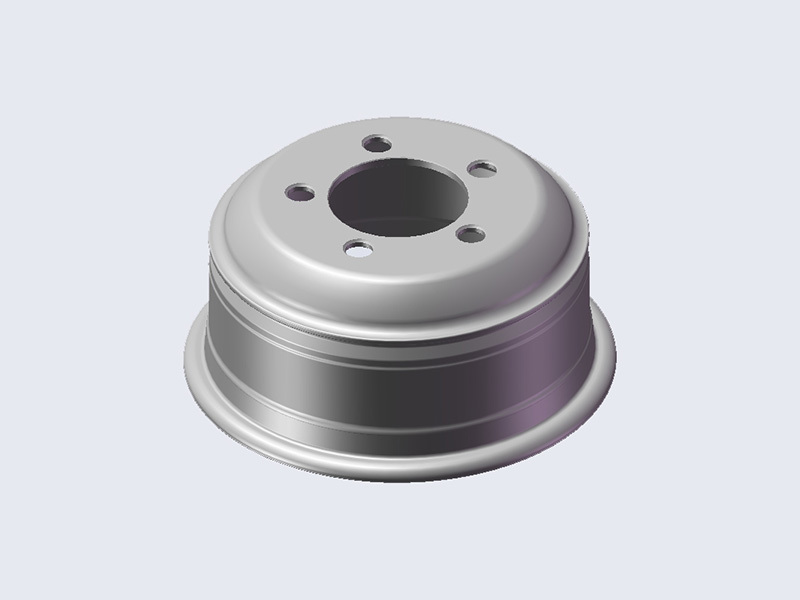

Bimetallic brake drum

Bimetallic brake drum

Bimetallic brake drum

Aluminum alloy steel rim

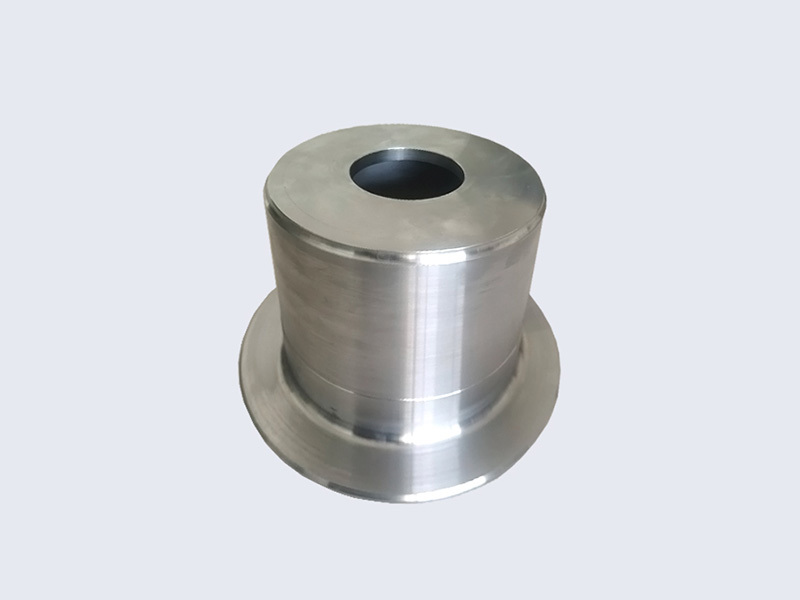

Wheel edge reducer housing

Bus wheel hub

Introduction

The PCX-3045 CNC double-wheel vertical spinning machine developed by our company uses the Siemens CNC and drive system from Germany, along with Rexroth servo valves. The currently developed spinning products mainly include automotive wheel spokes, brake drums, integrated steel rims, and wheel-side reducer housings. For thicker and more complex products, multiple spinning processes can be used, expanding the application range of the spinning machine. Compared to programmable spinning machines, it achieves diversification and cost-effectiveness of spun products, improving the performance of spun products.

The column of the spinning machine adopts a frame structure, and the base is made of a single casting to ensure the rigidity and stability of gravity spinning. The spindle uses a permanent magnet synchronous motor with high torque and small size. It also detects and adjusts the spindle motor speed in real-time through an encoder. The spindle speed can be programmed in the CNC system, allowing adjustments based on product characteristics during spinning to ensure geometric accuracy and surface finish of the product. The axial and radial feeding of the spinning wheel is controlled by CNC programming interpolation with fault diagnosis alarm functions.

The frame-type CNC spinning machine mainly employs digital control technology, providing good precision during product processing. The programming speed is fast, and programs can be saved internally or externally in the CNC spinning machine system for easy retrieval later. The main structure uses ZG35 cast steel construction with high structural strength; the lifting shaft part uses wedge-type adjustable V-guides for reasonable structure and convenient adjustment. The horizontal shaft part employs wedge-type square guides with high strength for smooth operation and easy adjustment. The CNC system utilizes German Siemens CNC and drive technology, while the hydraulic system uses Rexroth components from Germany, featuring high control precision, large load capacity, and high reliability.

The hydraulic system is a self-developed design by our company that provides stable power for the entire spinning machine. The oil pump motor is controlled by Delta oil-electric servo drivers in conjunction with a large flow vane pump to provide stable pressure and flow for servo valves. This allows precise control over product processing dimensions and accuracy.

Our company holds independent intellectual property rights for CNC spinning machines.

Key words:

Numerical Control Spinning Machine

Previous Page:

Next page:

Message

Related Products