Products

Numerical Control Spinning Machine

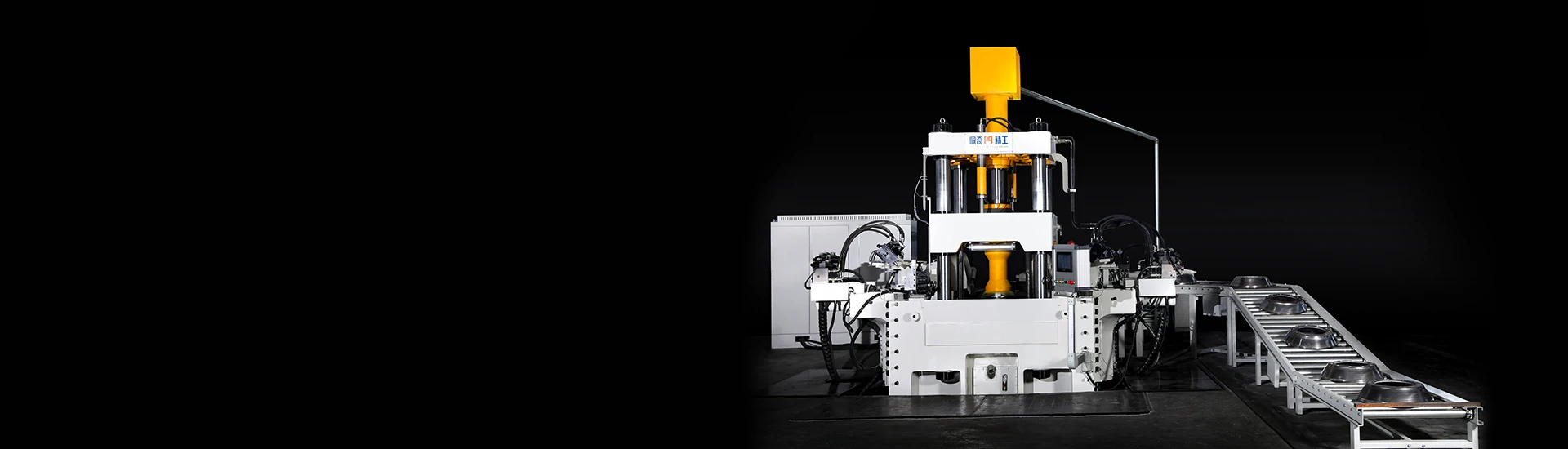

The frame-type CNC spinning machine mainly adopts digital control technology, providing good precision during product processing, fast programming speed, and the ability to save programs either internally or externally in the CNC spinning machine system for easy retrieval later. The main machine structure uses ZG35 cast steel, which has high structural strength. The lifting shaft part employs a wedge-type adjustable V-guide rail, which is advantageous due to its reasonable structure and ease of adjustment. The horizontal shaft part uses a wedge-type square guide rail, offering high structural strength and smooth operation with convenient adjustments. The CNC system utilizes German Siemens CNC and drive technology, while the CNC hydraulic system employs German Rexroth components, featuring high control precision, large load capacity, and high reliability.

The body, movable beam, top plate, and the base of the profiling cylinder are all made of high-quality impact-resistant castings, and the design of the high-strength load-bearing mechanism improves the processing rigidity of the equipment.

The CNC vertical lathe is a self-innovated and developed dual-channel CNC vertical lathe, mainly designed for the specialized equipment for processing automotive wheel spokes. This equipment features a dedicated tool holder on the main tool post, with tool bars that enhance stability during the cutting process, resulting in high production efficiency for wheel spoke machining. The machine is also suitable for integration with automatic lines and has good versatility. The dual tool holders can simultaneously perform turning operations on inner and outer holes as well as different curved surfaces. The operating system uses the Guangzhou CNC 980TTc dual-channel CNC system, which is currently widely accepted and maturely stable, making it easy for operators to quickly master and operate proficiently.

The specialized multi-hole drill for wheel spokes is an essential piece of equipment in the production process of wheel spokes. It can enlarge the screw holes of the wheel spokes and complete the machining in one go. By pre-setting the distribution circle diameter and the number of screw holes, it ensures that the positions of the spoke screw holes meet design requirements. This equipment features high production efficiency, accurate dimensional positioning, convenient operation, reliable performance, and simple maintenance. The device is designed with high transmission efficiency through computer simulation and finite element analysis, making it an ideal machine for processing wheel spoke screw holes.

PQXC3 - The valve hole special milling machine is independently developed by our company and is a patented product with independent intellectual property rights. It comes with universal fixtures that can be used for milling various spoke valve hole notches. The position of the universal chuck jaws can be adjusted according to the size of the center hole of different spokes to accommodate different sizes of center holes.